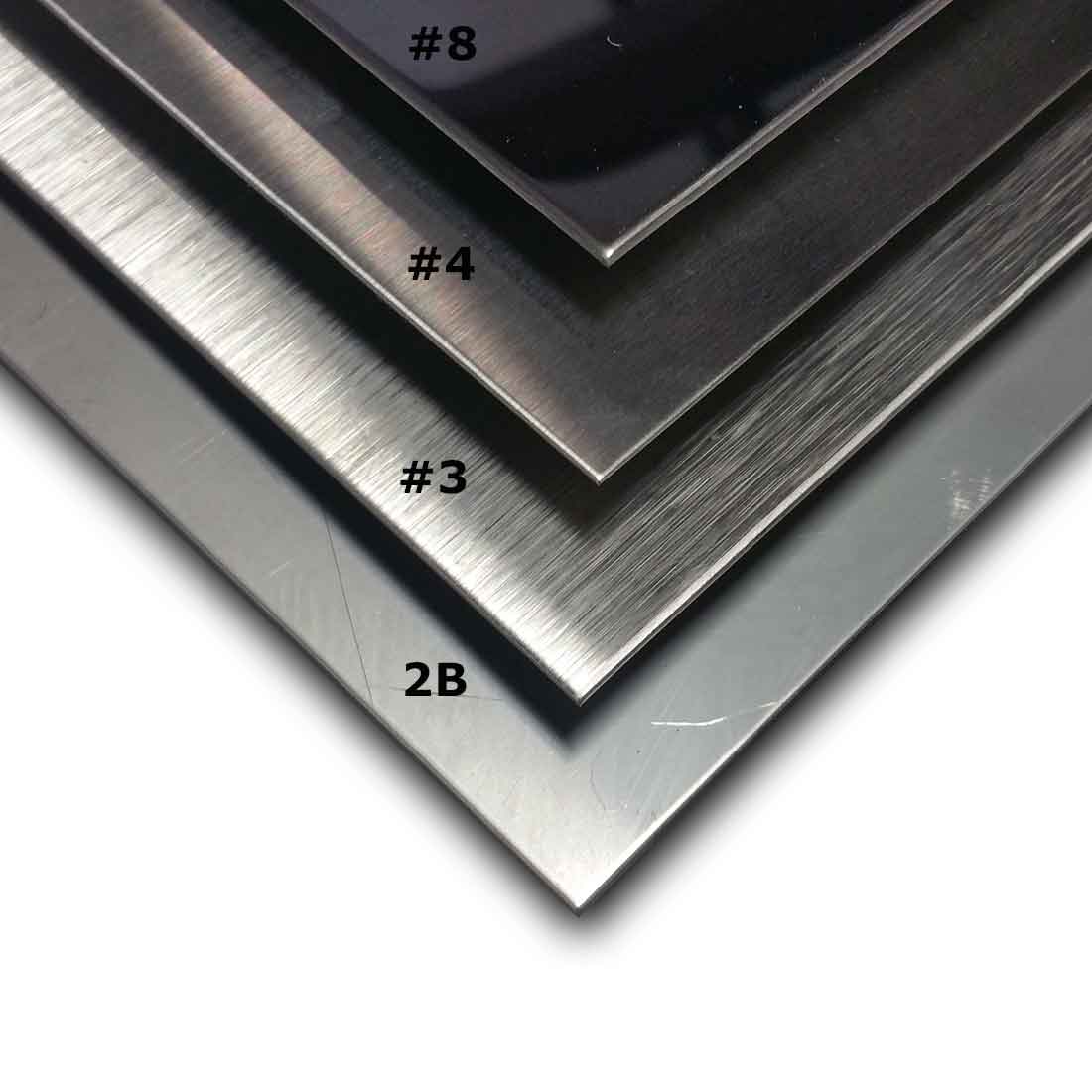

From mill finishes to applied finishes the stainless steel finishes that are applied to the surface of your stainless steel can play a bigger role than you may realize.

Stainless steel sheet finishes chart.

Stainless steel grades and finishes.

It has become popular in kitchens due to its low maintenance cleanliness appearance and corrosion resistance to food acids and water.

It is important therefore to check that the finish is available in the form required.

The profiled stainless steel sheet clad counters of this bank in flensburg germany were ground to provide a lively contrast to the smooth wooden surfaces.

While some products may only require standard stainless steel finishes others may need something extra in order to enhance surface appearances improve environmental.

Sheet plate bar tube but all finishes may not be available on all forms.

The chromium slows down the corrosion process and plays a key part in defining stainless steel.

Guide to stainless steel finishes 2g a uniform uni directional surface that has low reflectivity.

Generally the higher the chromium percentage the more corrosion resistance.

Stainless steel is polished by mills in a range of forms e g.

The following list of stainless steel sheet finish chart designations includes a short description of how each surface may be obtained.

A dull finish produced by hot rolling to a specified thickness.

Mechanically applied finishes may.

What is stainless steel.

Stainless steel sheet finishes.

Basic stainless steel sheet finish designation.