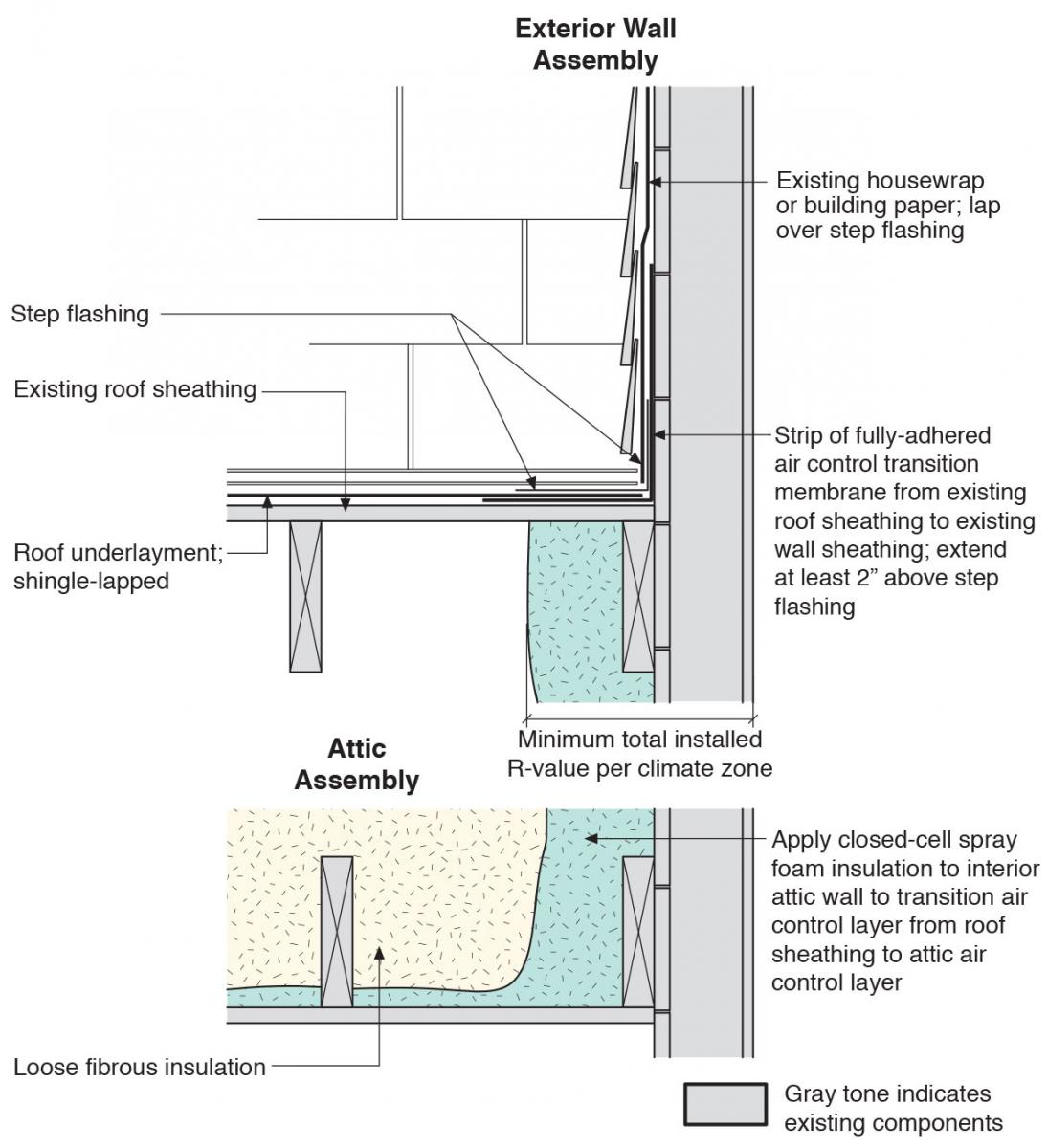

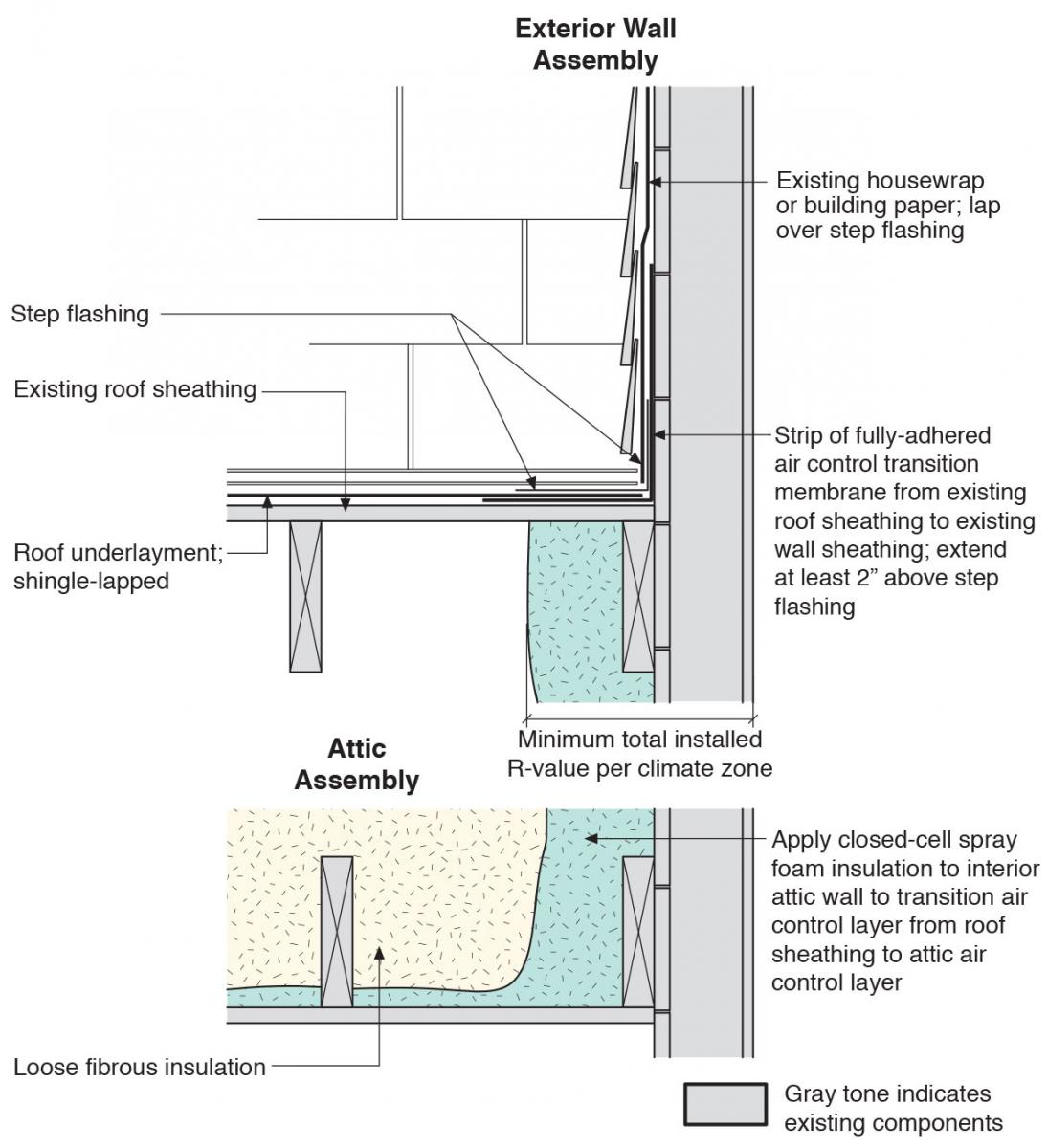

The flashing extends up the wall at least 4.

Step flashing roof wall connection.

Then set the piece down.

Nail through flashing into shingle do not extend flashing above top of shingle and.

Step flashing is used to provide a water tight connection where roofing adjoins a vertical juncture.

Ensure it sits flat and extends at least 8 inches above the shingles.

Bend it back so that it overlaps the corner flashing.

Keep doing this until you run out of stepped blocks.

2 fold a vertical strip into the inside corner extending it above the top of the block so that the next layer of flashing will cover it shingle style.

1 run membrane down the side of the block and onto the roof underlayment.

The flashing extends onto the roof a minimum of 2 inches 4 inches is preferable in more severe climate areas.

Continuous flashing against a sidewall is one way to install a roof but it s not the correct way.

Even if one piece of step flashing fails the flashing and shingle below it start the process over again.

Bent into an l shape.

Step flashing step flashing redirects the water back onto the shingle.

Check out our recommended tools right here.

Vent flashing done right to prevent leaks back up roof vent boots with flashing counterflashing and proper shingling.

Step flashing should be integrated with the drainage plane above for example overlap housewrap over it.

Here s how to do it right the first time.

Nail it in place with two nails one.

And 3 cap the block with membrane overlapping the first two pieces and bridging the gap between the block and the wall sheathing.

How to install step flashing with a wall corner step three.

Step flashing should be extended at least 4 inches up the wall from the roof deck and at least 4 inches out along the roof deck 2015 international residential code irc.

Cut step flashing pieces to be 10 in.

Epdm flashing tape with a butyl adhesive backing will help.

Cover tops of step.

How to install roof flashing against a wall.

Wide and 2 in.

Hammer one nail to the.

Longer than the shingle s exposure.

Flashing joints are lapped 6 in the direction of water flow.

Here s how to install it correctly.

Galvanized sheet metal bent at a 90 degree angle i e.

The metal flashing is formed with a hook edge and cleated on 12 centers.