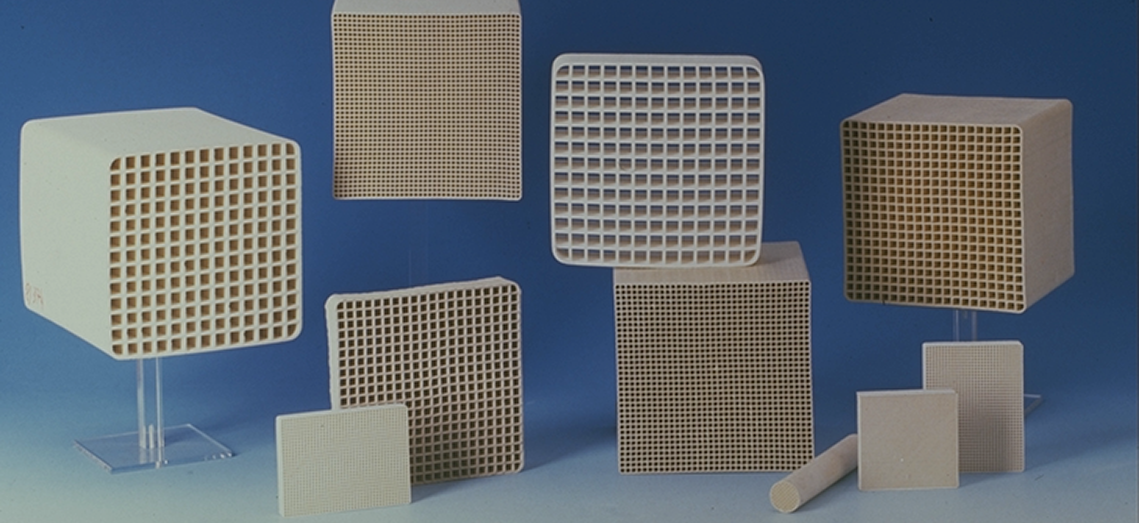

Oxidizers inc has performed many ceramic media studies to help customers determine the best ceramic media in terms of operational pressure drop thermal dynamics and ease of use replacement.

Thermal oxidizer ceramic media beds.

These are all signs of a thermal oxidizer that should be evaluated for media replacement.

Effective ceramic media enable the rto to function correctly and a well functioning system supports continuing operations along with environmental compliance.

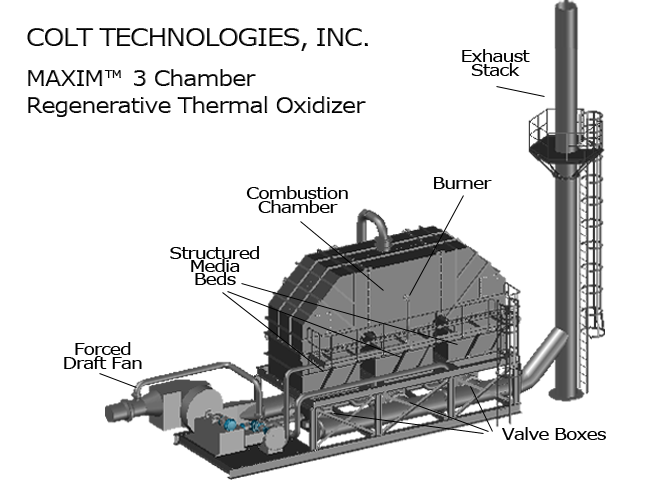

Best suited for large air volumes with high concentrations of vocs the regenerative thermal oxidizer aka rto boasts the best thermal efficiency of all oxidizers.

The primary advantage of the rto design is the ability to capture and re use waste heat.

Saint gobain norpro has developed and manufactured more heat transfer media than any other company in the world.

As part of preventative maintenance the cmm group provides ceramic media inspection and replacement for regenerative thermal oxidizers rtos thermal oxidizers and rotary concentrators both cmm and other makes.

Using two or three beds of ceramic media the rto design captures waste heat and stores it in the ceramic media.

Optimize your regenerative thermal oxidizer s rto performance with saint gobain norpro s advanced heat transfer media.

Tour of regenerative thermal oxidizer combustion chamber and ceramic media bed.

Ceramic structured media combines the high heat capacity and low pressure drop of a honeycomb monolith shape with the chemical stability of the high alumina composition making it particularly suitable for use in regenerative thermal oxidizer rto and regenerative catalytic oxidizer rco applications.

The condition of a regenerative thermal oxidizer s rto ceramic media is crucial to system performance.

Cmm group provides complete and turnkey ceramic media replacement including inspection removal and installation and repairs.

Outgoing hot gases heat the ceramic media beds which then heat the incoming pollutant air.

15 000 scfm capacity rto ceramic fiber insulation modules line the chamber walls constructed of 1 4 mild steel plate.

Regenerative thermal oxidizers and regenerative catalytic oxidizers rtos rcos will experience over years of operation reduced air flow capacity channeling or voids in the media bed thermal imbalances in the chambers non efficient energy use and extended startup times.